HS2 and HS4-are high strength glass fibers made from magnesium alumina silicate system which meets the needs of military and other applications where high strength and high performance is required.

S-Glass is generally used for polymer matrix composites that require improved mechanical properties compared to E-glass based composites. This is often the case when the material is operated under more extreme conditions.

S-Glass will has the same working qualities as a standard E-glass, however you will gain an approximate 25-30% increase in breaking strength. Used in applications where the most possible strength is required while keeping weight to a minimum.

Application:

Aerospace, marine and arms industries due to its high tensile strength and higher modulus of elasticity when compared to e-glass.

Advantageous:

l 30 to 40% better tensile strength.

l 16 to 20% higher modulus of elasticity

l 100 to 150 degrees celsius better temperature endurance

l 10 fold higher fatigue resistance

l Excellent impact resistance because of the high elongation to breakage

l High ageing and corrosion resistance

l Quick resin wet-out properties

l Weight saving at the same performance

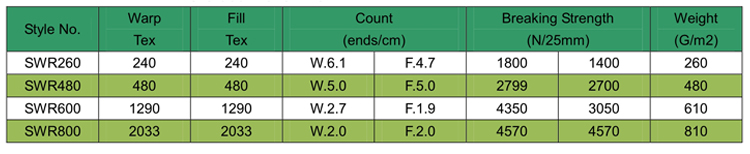

Main Specifications for S Glass Woven Roving:

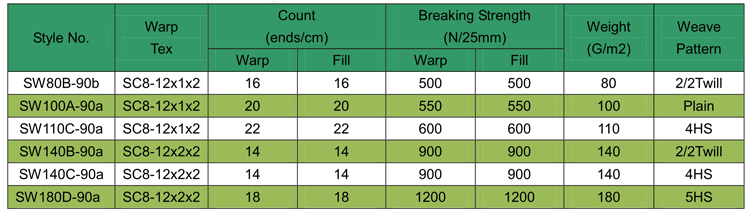

Main Specifications for High Strength S Glass Fiber Fabric:

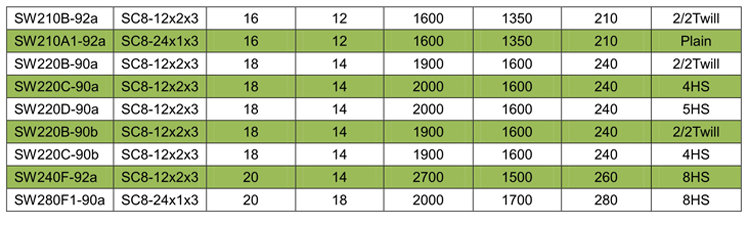

Main Specifications for High Strength S Glass Fiber Fabric: