Vermiculite board is made from a naturally occurring aluminium-magnesium silicate layer that has been already expanded with the application of heat. This expansion process is called exfoliation and the resulting material is used in bulk form or processed to boards by a press forming process. The board can be worked easily with wood working tools. It can be sawn, drilled and sanded.

Application:

(ClassA):

l A1-A3 products can be directly applied to hot side of low temperature oven, drying oven etc

l A1-A3 products can be applied at the back side of refractory bricks in various high temperature industrial furnaces. It best fit for combined use with high temperature refractory insulation bricks

l Widely used as heat insulation board for furnace, kilns, pizza ovens, hot compression mcolding machines. heating induction furnace

(ClassB):

l According to Class A

l Backup material for industrial furnace, heat insulation material for burning machine

l Heat insulation material for fuel charger

l Backup material for tunnel kiln, blast furnace, tube firing table

l Heat insulation material for steel making machine

l Heat insulation board for aluminum melting furnace

l Heat insulation board for glass melting furnace

(ClassC):

l Interior decoration material for various industrial furnaces heavy loading part, shock absorbing part, high wearing part etc

l Combined use with high temperature refractory bricks

l Applied as heat insulation material at high temperature, high heat insulation requirement parts in industrial furnace, melting furnace burning machine, steel industry ete.

l Insulation material for various industrial machines

Dimension:

l Max Length=1200mm, Max Width=1000mm, Min Thickness=10mm, Max Thickness=100mm, Desnity=400-1200kg/m3

l Can design into various shapes according to customer requirements

l Kindly understand that irregular board will cost a model charge

l Can be machined into different shape and cut into different size according to customer requirements

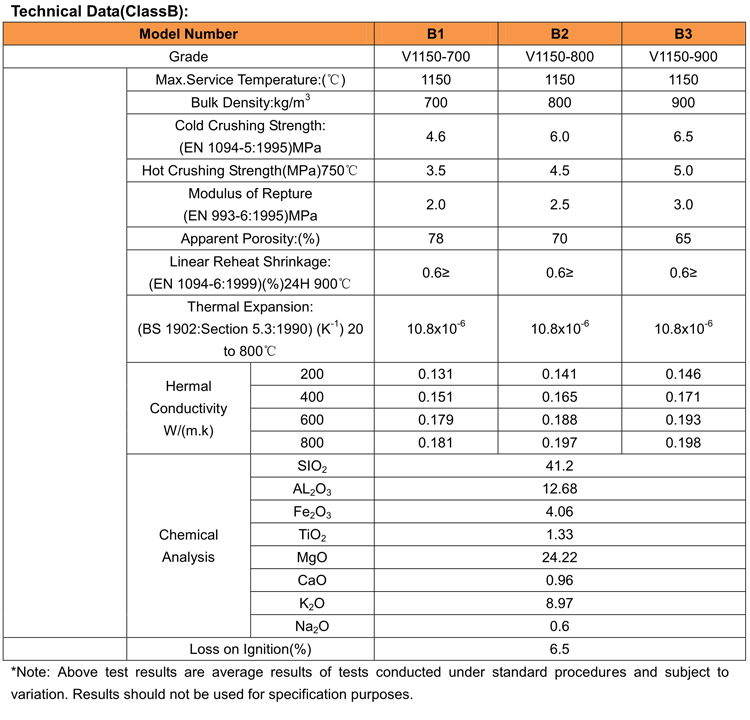

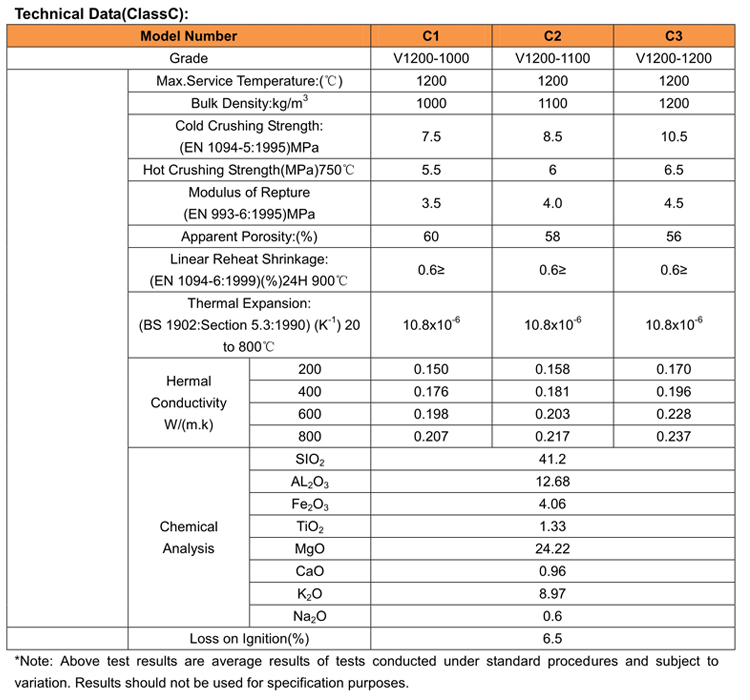

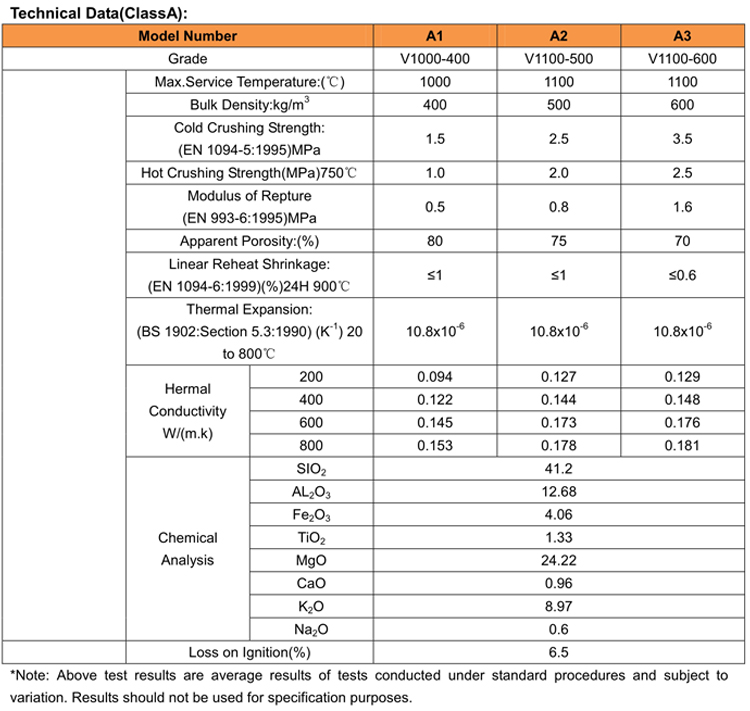

Technical Data: